Our CNC bending machine is equipped with a dedicated Industry 4.0 interface, enabling seamless integration with robotic arms for fully automated loading and unloading operations.

Integrated with the Lichuan self-driven robotic arm, this bending machine shares a unified control system with the bending center, eliminating the need for additional programming during workpiece changes. The system automatically generates robotic arm movements based on bending commands, enhancing efficiency and ensuring seamless coordination.

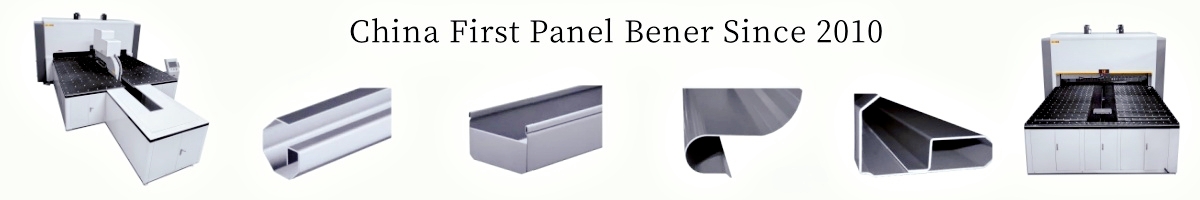

About Us

Extensive experience in Cold Roll Forming since 2004.

Specialized in HVAC Ducting Machinery development since 2006.

Expertise in Automatic Duct Production Lines dating back to 2008.

Pioneered China’s first intelligent bending center for a Saudi client in 2010; project paused due to servo motor precision limitations at that time.

Awarded 52 patents for Panel Bending Machines from 2016 to 2025.

The sole manufacturer in China producing intelligent bending centers with a bending height of up to 700mm.

Q1: What is a bending machine?

A: A bending machine is equipment used to bend metal sheets into desired shapes, widely applied in sheet metal processing and manufacturing industries.

Q2: What types of bending machines are there?

A: Common types include manual bending machines, hydraulic bending machines, CNC (computer numerical control) bending machines, and intelligent bending centers.

Q3: What is the maximum bending thickness of a bending machine?

A: The maximum bending thickness depends on the model and specifications of the machine, generally ranging from a few millimeters to several centimeters. High-end machines can bend thicker materials.

Q4: How to choose the right bending machine?

A: Choosing a bending machine depends on factors such as material thickness, size, bending angle requirements, automation level, and budget.

Q5: What are the advantages of CNC bending machines?

A: CNC bending machines offer high precision, automated operation, programmable processing, high production efficiency, and excellent repeatability.

Q6: What are the key maintenance points for bending machines?

A: Regularly check hydraulic oil, lubricate mechanical parts, calibrate bending angles, and keep the machine clean to ensure proper operation.

Q7: What materials can a CNC bending machine bend?

A: Mainly used for bending metal sheets such as steel, stainless steel, aluminum, and copper.

Q8: What safety precautions should be taken when operating a bending machine?

A: Operators must be trained, wear safety gear, keep hands away from the bending area, and maintain the machine properly and cleanly.

11